Crusher Saliant Features : BODY

It is fabricated from best Quality heavy duty structural steel plates.electrically welded with high strength welded material. The area of weld is increased to enable to get more strenght and rigidity.

The stress relieving is done by giving specific temp in furnace which withstand more hammering impacts and crushing pressure, it also increases its durability. The body performance would be definitely better. .

Crusher : JAW STOCK (MAIN ARM)

Heavy duty steel casting as I.S. grade. It is duly annealed and toughed conditions having longer durability at higher working load.

Crusher : JAWS

Heavy weight jaws are provided of special alloys magenese steel as aproved by ISI grade.

Crusher : FLY WHEELS

Heavy duty Fly wheel are provided of cast iron with perfect balancing to get the zero vibrations.

Crusher : BEARINGS

Four numbers heavy duty self aligning spherical roller bearings are provided bearing are selected at higher range to with stand heavy redial and thrust load.

Crusher : SHAFT

Crank shaft are made from forged steel having higher grade EN series with Heat-Treatment processes like hardening and tempering for toughening the shaft strength. Ultra Sonic and hardness testing are done.

PULVERISER

Hovert Machines is a high swing type grinding mill pulverisation is achieved by the impact of the grinding chamber. The fine Powder is swept by the blower suction from the grinding chamber via whizzer cone. The function of whizzer cone is to check the oversize particles and thus to regulate fineness SAND IS SEPARATED OUT from material from the grinding chamber by a special arrangement at an extra cost.

The blower delivers the pulverised powder in the cyclone air separator. The powder is discharged from the cyclone spout. The separated air return to the grinding chamber to complete the air circle.

The excess air is bled off through dust collector filter bags. The extra fines are collected there.

Hovert Machines is an ideal unit for grinding non-abrasive soft medium and hard minerals and also Gram-dal tamarind seed. The pulveriser is manufactured from best raw materials. The main body of the grinding chamber whizzer chamber and the blower are made of heavy duty cast iron every portion which comes in contact with the materials is lined with heavy duty steel plates. The striking face of the grinding chamber is lined with hard iron replaceable plates. Thus protecting the machine from wear and ensuring it for long life. The grinding chamber is provided with a pocket in which small pieces of iron nuts and bolts are trapped.

The main drive shaft is run on two double row self aligning heavy duty Ball or Roller Bearings.

IMPACT PULVERISER (Fineness upto 325 Mesh / 43 Microns)

" Designed as per individual Product requirement based on our grinding experience "

Hovert Machines are impact type, high speed, air swept, swing hammer type, multipurpose grinding mills capable of grinding soft to medium hard minerals & chemicals upto the hardness of 2.5 - 3.0 Mohs. The Pulveriser is supplied with a hopper below which is a Star Feeder actuated by a Pawl & Ratchet Mechanism. Fine Grinding is achieved by compression, shear, abrasion, attrition and impact of Hammers on the materials against the replaceable Radial Liners.

The Pulverised Product is sucked by the Strong suction Centrifugal Blower through internal Whizzer Classifier. In between the Centrifugal Blower and Grinding Chamber is the internal Whizzer classifier consisting of blades with tips tapered to confirm the degree of Whizzer Cone. The Coarser material is thrown back into the grinding chamber for re-grinding and only fines pass though it. Fineness can be controlled by clamping the clamp at a suitable position. The entire wearing portion consisting of Grinding Chamber, Whizzer Cone and Centrifugal Blower are lined with replaceable lining plates.

The Function of the High Efficiency Cyclone Air Separator is to separate the Pulverised material from Air which is re-circulated in the Grinding chamber to complete the closed circuit grinding action. Excess Air coming in the system is bled off through Dust Collector.

The main mill is supplied with Automatic Feeder, High Efficiency Cyclone Air Separator & Dust Collector. The material of construction of internal parts of Pulveriser main mill, cyclone air separator & dust collector varies as per individual requirement. The Pulveriser is supplied with Digital (Automatic) Feed Controller for maximum feeding.

Star Features:

Pulveriser Supplied With:

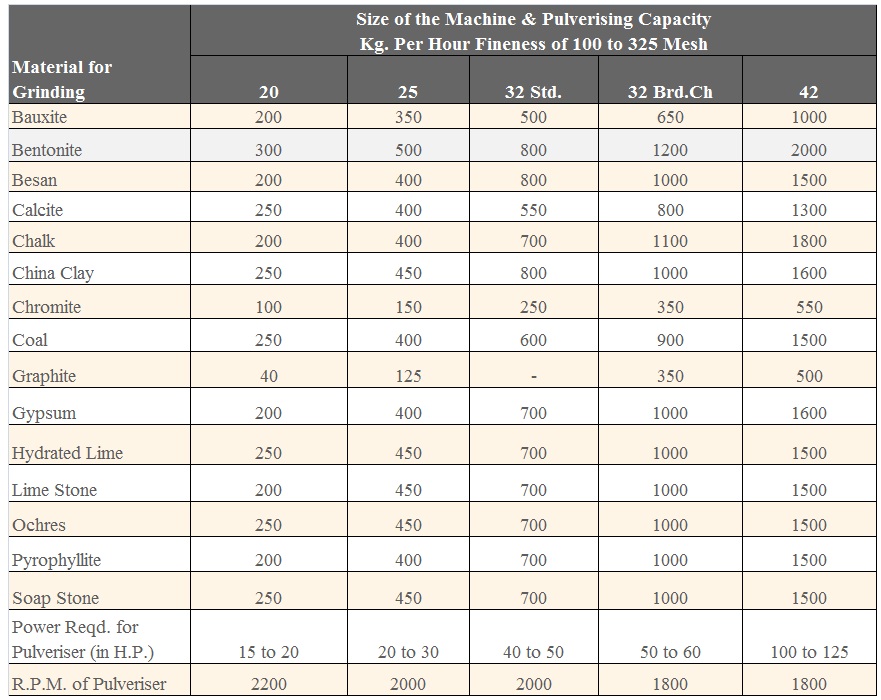

Given below is the table indicating the pulverising capacity on average basis however the capacity figures will vary from case to case depending upon several factors. These figures are meant for guidance only.