EFFLUENT TREATMENT PLANTS

High concentrations and fluctuations of organic matter characterize dairy wastewater. We bring a high tech effluent plant to treat dairy waste. We have both anaerobic and aerobic treatment plants to ease out our clients in managing dairy wastes.

We offer a wide range of effluent treatment plants on turnkey basis. The company has evolved design and methodologies for treatment of complex effluents which have toxic interference due to presence of cyanides, phenols, arsenic, heavy metals, solvents etc. We provide user-friendly treatment systems based on Physico-chemical and Biological oxidation for treatment of waste water from chemical, fermentation, pharmaceuticals, phosphating and electroplating industries. We also offer consultancy for modification and up gradation of the existing treatment facilities to achieve desired results and also to reduce operating cost. Several effluent treatment systems have been provided with tertiary treatment for recycling and conserving water

REVERSE OSMOSIS SYSTEMS

The RO System works on the principle of Reverse osmosis, also known as hyper-filtration. One of the finest techniques for treating water, reverse osmosis eliminates contaminants from water thus making it fit for drinking purpose and other commercial and industrial applications. The RO system is provided with sediment pre-filter and an activated carbon filter as the membranes are degraded by chlorine, bacterial attack, manganese, hydrogen sulfide and iron. Advanced models of RO Systems are also attached with water softeners.

Available As:-

Working:-

Stage 1: Removes dirt, sediment, sand and other physical particles.

Stage 2: Granular Carbon Filter which reduces chlorine, organics, odor, smell and turbidity from water.

Stage 3: Block Carbon Filter that further reduces chlorine, odors and other chemicals.

Stage 4: Reverse Osmosis Membrane in which bacteria, heavy metals, salt, bad mineral substances and other dissolved matter and chemical drugs are removed from water.

Stage 5: Rear anti-bacteria activated carbon filter that improve the taste of water.

Technical Specifications:-

Allowed pressure for source water : 0.1-0.3Mpa

Work temperature : 5-40? Max of original water

TDS : 1000ppm

Output : 100-400G/Day

Flush Type : Auto flush

Fitting : Common fitting or quick connect fitting

Volume of pressure storage tank : 11G Rated voltage

Frequency : AC220V/50Hz

Rated power : 50W

Precision of purification : 0.0001um

Transformer : 24V(220V)

Application Areas:-

RO Systems are used in Homes, offices, hospitals, clinics, Nursery homes, beauty salons, gyms, schools, restaurants and shops.

COMMERCIAL REVERSE OSMOSIS PLANT

Commercial Reverse Osmosis Plant removes all the impurities from water making it fit for varieties of commercial activities. Installed at commercial establishments like shopping malls and hospitals, the commercial RO plants are considered as the most cost effective water treatment system. It cleans the water from contaminants and removes non essential, metals, corrosive salts and chemicals present in the water.

Working

Pre-Treatment Clarification of water Sand filtration Water softening for reducing the hardness Water is passed through activated carbon filters Final removal of suspended particles using cartridge filters Post-Treatment Oznonation Ultra-violet Chlorination Systems

Technical Specifications

Voltage : 5 HP

Duty Cycle : 12 h

Production Capacity : 100 LPH (Liter per hour) to 100 M3 per hour

Output TDS : 400 TDS to 45,000 TDS

Membrane : 4 No 4040

Dimensions : 4¡¯ x 2¡¯ x 4¡¯ (l x b x h)

Inlet Water Pressure : 7 Kg to 14 Kg

Filter Cartridge : 3 No 20¡¯ each

Booster Pump : Multi Stag

Application Areas

The Commercial Reverse Osmosis Plants are widely used for:Purification of Drinking Water, Dialysis, Reef aquariums

INDUSTRIAL REVERSE OSMOSIS SYSTEM PLANT

Industrial reverse osmosis system plant is best suited for small and large scale industries. This type of reverse osmosis plant can be configured easily as per the individual requirements of output water. It produces high-quality demineralised water for various industrial applications. A systematic programme is integrated in the plant for studying the chemistry of water. Depending upon the contamination level of water, the RO plant itself selects the most suitable membrane configuration to provide a plant which gives a low water-rejection rate.

Working

The input stream water is first passed through Pressure sand filter Unit Removal of suspended matters and turbidity from water Filtered water is then passed through activated carbon filter Color, odor, chlorine, oil& grease get removed from raw water For removing micron sized particle, the water is then passed through micron cartridge filter The purified water is then stored in a storage tank with disinfection units

Technical Specifications

50 to 2000 Liter per Hour capacity

Output TDS : 10-50 ppm (input water with TDS levels under 600 ppm)

Pressure : 20 psi - 60 psi

Free Chlorine : 0.1 ppm

Temperature : 35¡ÆF - 85¡ÆF

PH : 5.8 - 10

Silt Density Index : 5 (max)

Electrical : 1/ 3 phase, 220-230/440Volts

AC supply Turbidity : 1 NTU (max) System Efficiency Percentage ionic rejection >96% Percent recovery 50-75%

Application Areas

Effluent and wastewater purification, Food processing industry, Car washing, Hydrogen production, Fruit syrup production, Beverage industries

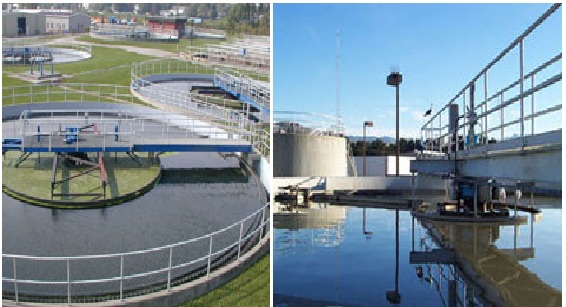

SEWAGE TREATMENT PLANTS

Sai Ram Engineers offers complete solution for Sewage Water Treatment Plants and Recycle. The Sewage from the residential and commercial buildings is treated for reduction in BOD, COD & TSS in order to comply with the pollution control board standards for disposal, gardening, flushing and other non-potable purposes.

The sewage treatment plants are based on the Latest FAB (Floating Aerobic Biomedia) or SAFF (Submerged Aerobic Fixed Film) treatment followed by clarification by a tube settler. Lime is dosed in for suppression of foaming tendencies. The clarified water is then further filtered in a Multi media Sand Filter after dosing of coagulant (alum) for removal of unsettled suspended impurities followed by Sand Filter and Activated Carbon Filter for removal of organics. The filtered water from ACF is then chlorinated & stored in the treated water tank

These sewage treatment plants are available in RCC constructed designs for commercial and residential buildings as well as Mild Steel FRP Lined and Fibre constructed tanks for easy installation and commissioning.

Sewage treatment systems are available from 50 M3 per day to 1000 M3/day and more...Water thus obtained can be used for gardening, flushing, car washing, etc...

Systems are offered for achieving zero discharge using UF and RO systems further to treat sewage.