MATERIAL HANDLING CONVEYERS

BELT CONVEYOR:

We are engaged in manufacturing Conveyors that is assured to have high quality standards. These include Belt Conveyors, Portable Belt Conveyors and Flat Belt Conveyors. Our entire range of industrial conveyors is custom made as per the specific technical details given to us by our clients. The equipment helps in reducing the man power requirement and is available as per the capacity of plants.

Overhead Belt Conveyor

We are offering Belt Conveyors that are known for meeting the severe adverse working conditions. These are appreciated by the clients for less maintenance, easy operation and long serviceability. To meet the specific requirement of our clients, we provide belt conveyors having 300 tons per hour (TPH). Available in horizontal and inclined type, these flat belt conveyors are extensively used for Solid Handling, Mineral handling like - Bentonite, Bauxite, Bag / Cartoon Handling, Sorting, packaging, Inspection etc & many more. We had serve various industries like

Inclined Belt Conveyors

Our Inclined Belt Conveyors are the most versatile and economical of all powered system. They convey a variety of regular or irregular shaped products from light to medium loads. They offer flexibility of conveying path like inclination, long term dependability and low operational cost We had serve various industries like

Flat Belt Conveyors

We are offering Flat Belt Conveyors that are perfect to use for light and medium weight loads between operations, levels and buildings. These are considered to be very useful when the conveyor path has an incline or decline. Flat Belt Conveyor are supplied for handling bags i.e., cement, sugar, chemical, cartoon etc with plain or rough top belt depending upon the requirement. We had also supplied Side wall type Belt conveyor with steep inclination for handling chemical, sulphur, minerals, these are used where spaced is the limitation with low maintenance & operation cost We had serve various industries like

Portable Belt Conveyors

We offer Portable Belt Conveyors that are perfect to use for all types of powered system. Offering flexibility of conveying path such as inclination, curve, long term dependability and low operational cost, these Portable Belt Conveyors are assured to have high quality standards. Our Portable Belt Conveyors are capable of conveying regular or irregular shaped products from light to medium loads. We had serve various industries like

BUCKET ELEVATOR

We are manufacturing a wide range of Bucket Elevator, which is used to carry bulk raw material and grams where continuous material flow is required. These vertical bucket conveyors are especially used where high capacities of material are to be handled but the floor plan or site space is limited. Our bucket elevator has gained huge accolades in the market for their sturdy construction and high performance. The detailed description of our Bucket Elevator is as follows : We provide Bucket Elevators that are considered to be perfect for vertical displacement of bulk solids and other goods. Manufactured using latest technologies, these Bucket Elevators are available in various designs and capacities with range starting few cubic meters per hour. These elevators are ideal for handling goods demanding extreme perfection and smoothness in running. Designed with proper selection of key components, these Bucket Elevators are offered with belt or chain type. Our Bucket Elevators are appreciated by the clients for handling fine free flowing, sluggish, aerated and friable material with significant percentage of lumps. Bucket Elevator Supplied with Centrifugal discharge, Continous Discharge and Positive Discharge.

EOT (Electric Overhead Travel) Cranes

Range: Double Girder and Single Girder EOT Cranes up to 500T capacity

We are the largest EOT cranes manufacturers in India. We have comprehensive range of heavy duty EOT crane systems (double girder, single girder, underslung etc.) of capacity up to 500 tonsfor various applications in power, nuclear, shipbuilding, steel plant, heavy/general engineering sectors etc. We recommend you the perfect customised solutions after doing an in-depth analysis of your applications, production facility, factory, and material handling requirements.

FEATURES:

CASTING CONVEYOR:

We are engaged in manufacturing a range of Ingot Casting Conveyor that is assured to have high quality standards. These conveyors are used to pour a number of moulds at a time with control over the volume of metal poured into each mould. This ensures minimum dross formation and consistent ingots. We also offer customized solutions for our Ingot Casting Conveyors to meet the specific requirements of our clients. Our range of Ingot Casting Conveyors includes following:

Ingot Casting Conveyor

We are offering a wide range of ingot casting conveyors that is appreciated by the clients for confirming to international quality standards. These conveyors are considered to be effective in pouring a number of moulds at a time. This is done with accurate control of the volume of metal poured into each mould and makes sure minimum dross formation and consistent ingots. Further, to meet the specific requirements of our clients, we also offer customization solutions based on their specifications. We had supplied Industrial Ingot Casting Conveyor for handling, lead handling, zinc handling with aluminium ingot of 6. 5 to 7 kg & zinc ingot 28 kg. Our mould are design as per international standard unable for easy ingot stacking.

Casting Conveyor

The present invention Casting Conveyors relates to apparatus for preparing molded articles, particularly for preparing liquid materials in molds and more particularly to preparation of multi-components, layered articles and to means for removing liquid from molds which contains solidified articles in solid and liquid form.

ROLLER CONVEYOR

We manufacture high strength Roller Conveyor that is manufactured and designed using latest technology. These are offered with sprocket at one terminal and a bearing housing at other. A roller shaft runs through the rollers, which are mounted on the extruded aluminum rails. Further, we offer customization solutions according to the specification of the clients. Our range of Roller Conveyor encompasses following: We provide a range of Roller Conveyors that is used to move the material from one place to other within a facility or project site. In order to offer quality range of Roller Conveyors, we use quality rollers in the manufacturing process. This material handling equipment is fabricated by using premium quality raw material to ensure their high standard durability and sturdiness. Roller Conveyor are gravity type or powerised type. Roller are galvanised or powder coated depending upon application. Supplied conveyor for drum handling, jumbo bag handling and cartton handling etc.

Powerised Roller Conveyor

We are engaged in offering Powerised Roller Conveyor that assures high performance and durability. The components of these conveyors are designed to deliver heavy duty usage as well as flexibility. They comprise broad walled rollers of sprocket, chain to chain or tangential chain mechanism, a fully enclosed side frame and an external shaft mounted motor. These powered roller conveyor comprises of component that are designed for both heavy duty usage and flexibility.

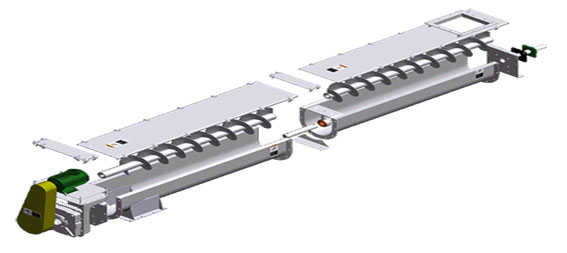

SCREW CONVEYOR

Screw Conveyor are manufactured with trough type or enclosed in a circular type & conveying horizontally or inclined or vertical with permitting intermediate discharge of the material at several points. Material Handle like Ice Cubes, Powder Coat, Food Colour, Pigments etc. Capacity from 1 TPLs to 50 TPLs. These conveyors are specially used for dusty, hot material and material with an obnoxious odor. Offered in small width, these are dust-tight by jacketing the trough. To meet the specifications of our clients, we offer a wide range of accessories such as loose Screw Flights (S.S. or M.S.). Moreover, we are engaged in designing various types of Screw Conveyors that includes