AGGLOMERATOR MACHINE

Our clients can avail from us a cost effective and efficient range of Agglomerator and Agglomerator Plants. These Agglomerators serve as ideal way for recycling thin polymers effectively and hence, are used heavily across plastic and scrap recycling industries. We specialize in manufacturing standard as well as customized range of Agglomerators as per the specifications from the clients' end. Our range of Agglomerators is best suited for PP, HDPE, LDPE, PVC and HM polymers with operational efficiency of 20 kg/hr up to 150 kg/hr and includes:-

- Processing Machines

- Plastic Processing Machines

- Plastic Processing Equipment

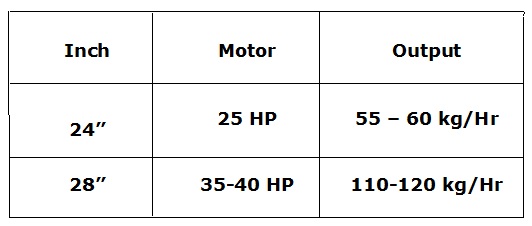

Technical Specifications:-

PLASTIC EXTRUDER MACHINE

Plastic Extruder machine based on more than 30 yrs. of experience in plastic Processing machinery. These plastic extruder machine and plants incorporate many silent features to give long & trouble free operation. The superior design ensures high output at low operating costs.

- Processing Machines

- Plastic Processing Machines

- Plastic Processing Equipment

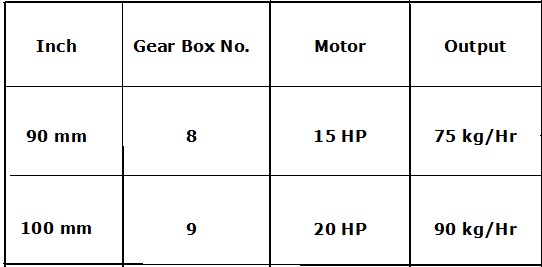

Technical Specifications:-

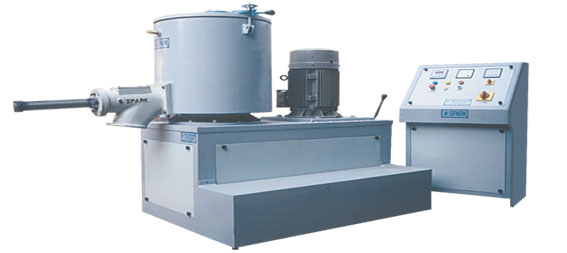

HIGH SPEED MIXER

We offer high speed mixer machines with superior quality at cost effective prices. These machines are manufactured by incorporating latest technology.

We specialize in manufacturing and supplying of heavy duty constructed High Speed Mixer. This mixer is appreciated widely among our clients for durability, performance and efficiency. The easy discharging arrangement and easy operation makes it a preferred choice over the available substitutes in the market. Low on maintenance, these mixers are used heavily for color mixing and pre heating all kinds of plastic material. Tabulated below are some of the key specifications of our range of High Speed Mixers:

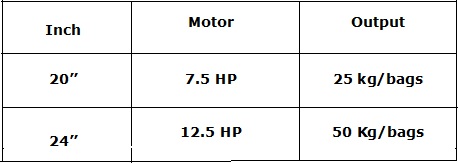

Technical Specifications:-

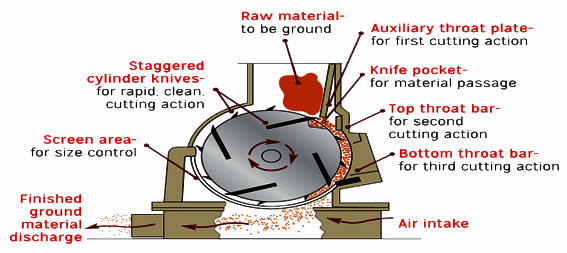

SCRAP GRINDER MACHINE

We are offering Plastic Processing Machinery like Plastic Scrap Grinder machine,High Speed Mixer Machine, Plastic Agglomerator machine,

Above all are pioneer & essential machinery in plastic Industry whether it is Rotomoulding, blow moulding or injection moulding.

The Application of plastic Scrap grinder machine is to Grind Plastic material in some pieces (in mm format)

The Size or outputs are different as per customer requirement

We are offering wide range of plastic scrap grinder machine; this machine is used to grind material like LLDPE, RPVC, PP. HD, PP, Pet Bottle, & plastic Chair scrap

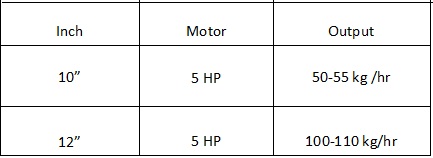

10-12 Scrap Grinder Machine

Technical Specifications:-

Hovert Machine is the pioneer of Plastic Scrap Grinder Machine, our scrap grinder machine is available in different model & different sizes, this machine is used to grind the material or we can say that the said machine is applicable to grind the plastic material like LLDPE, RPVC, PP. HD, PP, Pet Bottle, & plastic Chair scrap

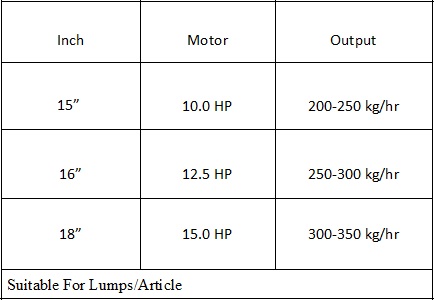

15-16-18 Scrap Grinder Machine

Technical Specifications:-

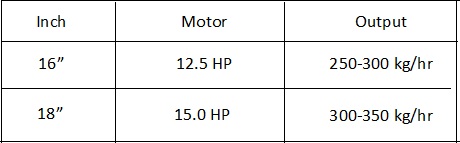

16-18¡± Scrap Grinder Machine

Technical Specifications:-

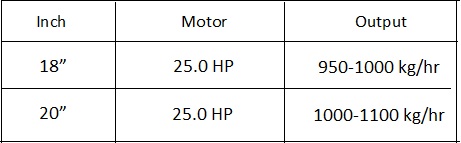

We have done the R & D , & developed Heavy duty scrap grinder machine these machinery gives customers more per hour production & able to deliver the expected per hour production

18-20¡± Scrap Grinder Machine

Technical Specifications:-

The scrap grinders manufactured by us find application in numerous polymer processing industry along with the roto moulding machineries .Fabricated using sturdy mild steel cutting blade , these grinders are used to recycle the plant waste and rejected articles.

WASHING & DRYING LINE

Washing line provide with fully automatic and semi-automatic (Individual machine) like

- Bale Opener

- Trommal

- PVC Label Remover/stripper

- Sorting Conveyor Belt with Magnet

- Wet & Dry Grinder/Granulator

- Friction Washer

- Sink-Float Tank

- Hot Reactor

- Centrifugal dryer / De-watering machine /Spin Dryer

- Hot Air Spiral Pipe Dryer

- Label Remover,

RECLAIMING OF:

- HDPE bottles

- Boxes

- Containers LDPE/PP

- Packaging film LDPE

- Agricultural film

- PP batteries.

RECLAIMING OF INDUSTRIAL SCRAPS PRODUCTION PROGRAM FOR POLYEFINE RECLAIMING, stated at point (A)

- Grinding

- Pre-washing

- Milling (with dry and wet mills)

- Washing process

- Centrifugation

- Drying

- Storage

- Waste water treatment system

TURNKEY COMPLETE PLANT

Net output:

- 500 Kg/h ¡¾ 10%

- 1000 Kg/h ¡¾ 10%

- 2000 Kg/h ¡¾ 10%

The obtained flakes can be transformed into granules with the extrusion lines, having the following outputs:

- 150 Kg/h ¡¾ 10%

- 300 Kg/h ¡¾ 10%

- 500 Kg/h ¡¾ 10%

- 750 Kg/h ¡¾ 10%

- 1000 Kg/h ¡¾ 10%

- 1250 Kg/h ¡¾ 10%